Features:

Polyethylene systems offer significant advantages over ductile iron, steel and concrete pipe systems.

• Corrosion Resistance: Polyethylene is basically chemically inert Systems do not rust nor corrode and resist chemical attacks from aggressive soils. Doesn’t react to salt or acids. No protective layer or finishing process is required

• Leak Tight: Butt fused joints create a homogeneous system, the fusion welds as strong as the pipe. Therefore, unlike ring type joints or other mechanical jointing systems, there is no risk of leakage resulting from joint distortion.

• Optimum flow rates: Smooth inside pipe surface allow for a high Hazen-Williams C factor. C remains constant throughout the lifetime of the system due to an innate high resistance to scale and biological build-up. Polyethylene is biologically inert.

• Excellent Water Hammer Characteristics to withstand Surges: the inherent properties of Polyethylene allow the system to significantly lower the effects of surges compared to PVC and Ductile Iron systems.

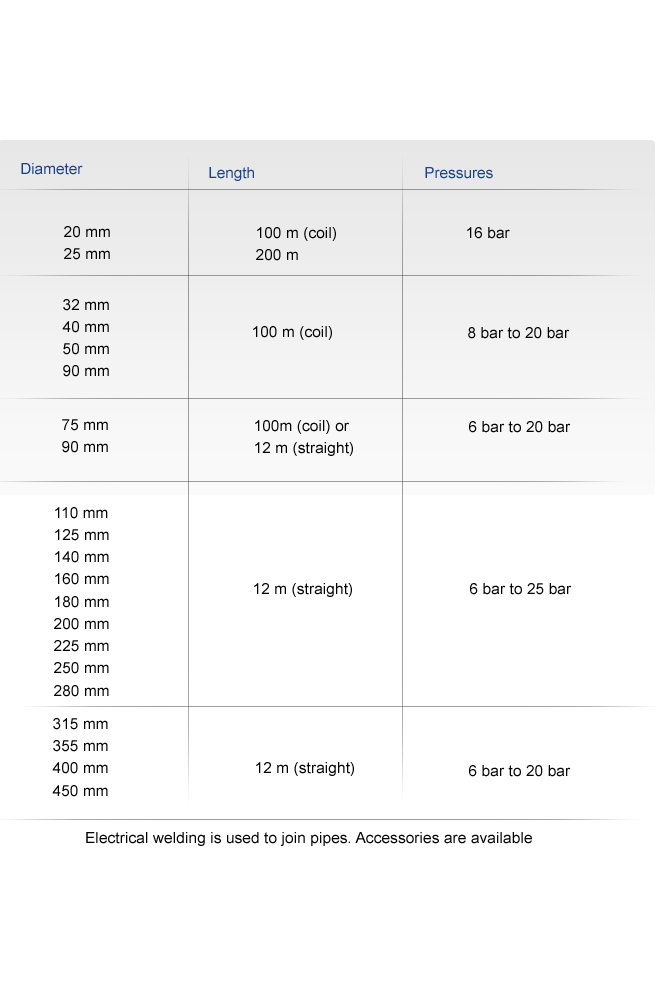

• Flexibility: allows PE pipes to be coiled and supplied in lengths of up to 200m for small diameter pipes. This feature is one of the many contributors to cost savings during installation.

• Resistance to Geological Conditions: A Polyethylene system has inherent resistance to ground temperature fluctuations and earth instability.

• High strain allowance virtually eliminates failure due to freezing pipes.

• Capable of holding external/outside high pressures

• Easy to transport

• Safe to health