Products

GLASS REINFORCED POLYESTER / VINYL ESTER PIPES AND FITTINGS

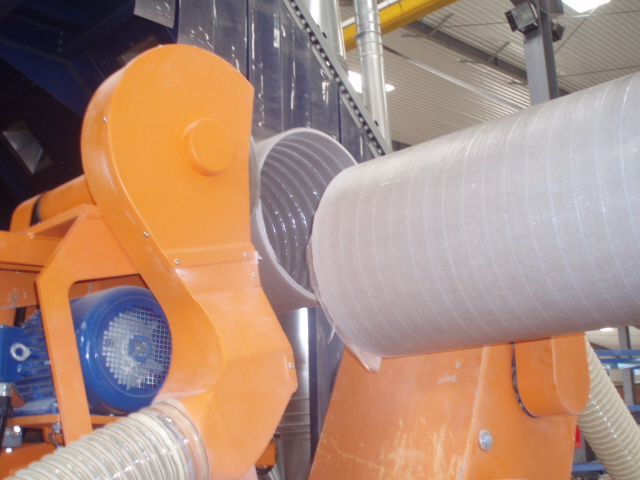

Production of GRP Pipes

Al Matin Pipes® manufactured by Al Matin Group is a composite material system produced from glass fiber reinforcements, thermosetting plastic resins, and additives. By selecting the right amount of materials and the manufacturing process, the designer can create a product to meet the most demanding requirements. Al Matin Pipes® is a leading manufacturing company that manufactures the GRP / GRV pipes. These pipes are available in nominal diameters ranging from 300mm to 2600mm. Pipes are available at different nominal pressure classes that are PN 3, 6, 10,16, 20, and 25 bars (PN 20 and PN 25 up to ND 2000mm) with stiffness classes of 2500, 5000, 10000, and 12500 N/m2. These pipes can be used for both underground and above ground installations depending whether it is a restrained type pipe system or non-restrained

Applications

Fiberglass pipe is used in many industries and for numerous applications including: Chemical processes, desalination, ducting and vents, geothermal, industrial effluents, irrigation, oil industries, potable water, power plant cooling, raw water, sewers, sea water intake and outfalls, slurry piping, storm sewers, water distribution, water transmission, and in tubing and casing.

Applicable codes and standards

ASTM D-3262, ASTM D-3517, ASTM D-3754, AWWA C-950, AWWA M-45, and BS 5480.

Characteristics

GRP pipes are known to be corrosion resistant, with a good strength to weight ratio, non-conductive material, has dimensional stability, low maintenance costs, and flexible.

Construction

GRP pipe is a composite laminate consisting of three layers mainly. The first layer is a corrosion resistant liner called the inner liner, the second layer is the structure layer, and the external layer is a resin rich layer The main three raw materials are: 1. Resin 2. Glass 3. Silica Sand Resin: Resin is one of the major components of fiberglass pipes. Resin enhances the chemical, mechanical, and thermal properties of the pipe when cured. Usually resin is mixed with other additives and a catalyst (hardener) in order to maintain the required viscosity and flow speed. The main additive is Styrene where this material is mixed with the resin in order to maintain viscosity. Thermosetting resins are known to be infusible and insoluble once cured. There are two types of resins used in the Al Matin Pipes® construction. The first one is the Isophtalic polyester and the second is epoxy based Vinyl ester. Glass: The mechanical strength of fiberglass pipe depends on the amount, type, and arrangement of glass fiber reinforcement. The quantity of the glass fibers and the direction of the individual strands are placed determines the strength. Fiber glass forms: Chopped glass: they are bundled, untwisted strands of glass fiber reinforcement and come as cylindrical packages. It is processed into chopped strand mat used to provide multidirectional reinforcement in pipes and fittings. Hoop glass: is a heavy fabric woven from continuous roving. This type of glass gives the pipe the hoop strength. Surface mats: light weight fiber glass reinforcement mats used to allow high resin content layers with minimal reinforcement. This surface gives extra environmental resistance for pipe and fittings, in addition to a smooth appearance. Silica Sand: Silica sand is used as filler. This filler may yield economic appearance, or performance advantages in fiberglass pipe.